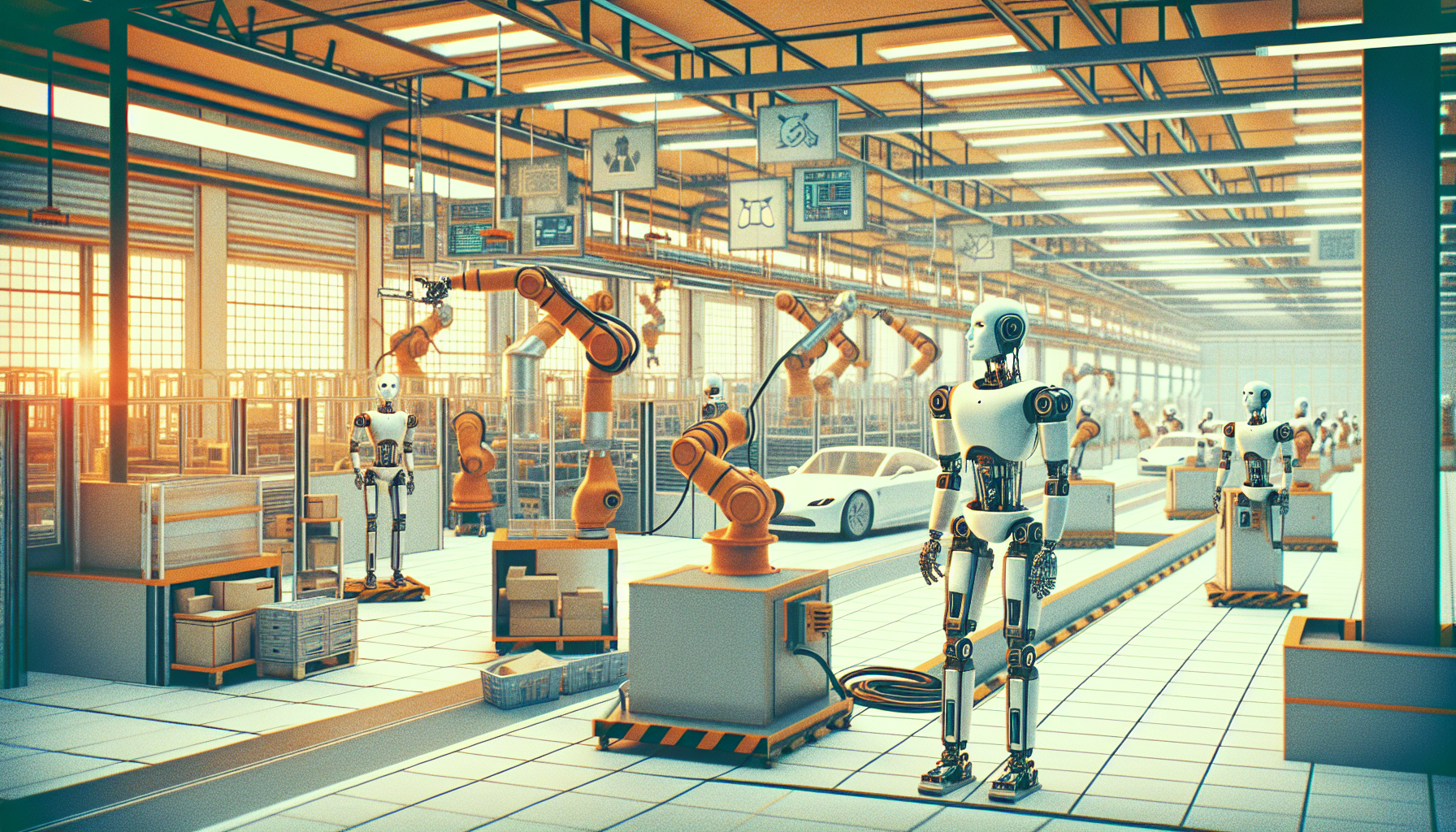

In today’s swiftly advancing world of industrial manufacturing, humanoid robots are emerging as game-changers. Especially in the automotive and warehousing sectors, these advanced machines are set to revolutionize how things are made. With abilities that mimic human dexterity, cognitive learning, and autonomous decision-making, they’re transforming production lines, improving efficiency, and tackling labor shortages.

Changing the Face of Automotive Manufacturing

Leading carmakers like BMW, Tesla, and Mercedes-Benz are leading the charge, integrating humanoid robots into their production processes. BMW, for example, is working with Figure AI to test these robots in real-world factory settings. The goal? To bring greater flexibility, automate tasks that were previously too complex for traditional machines, and boost overall factory automation.

Tesla, on the other hand, is developing its own humanoid robot, dubbed Optimus. This machine is designed to handle routine and physically demanding tasks in Tesla’s Gigafactories. Elon Musk has pointed out how vital Optimus will be for easing the strain on human labor and streamlining workflows.

Joining in is Mercedes-Benz, partnering with Apptronik to explore how humanoid robots can manage tasks that need a human touch — like handling materials and performing quality checks. Chinese carmakers like BYD and Geely are also jumping on board, leveraging their nation’s leadership in AI and robotics to advance automation in electric vehicle manufacturing.

The Power of AI and High-Tech Abilities

Artificial Intelligence (AI) is the powerhouse behind the rise of these humanoid robots. Unlike the robots of yesteryear that needed strict programming, today’s AI-driven humanoid robots employ machine learning, natural language processing, and advanced AI to boost their adaptability and decision-making.

Generative AI empowers these machines to tackle complex tasks, recognize patterns, and learn from human operators. This means they can sift through enormous data sets in real-time, make forecasts, and realign their actions based on instant feedback. Consider Figure 02, a humanoid robot tried and tested in car manufacturing; it has successfully inserted sheet metal parts with precision into their fixtures — a testament to its capability in executing complex manual tasks.

Economic Upside and Productivity Gains

Humanoid robots promise vast economic rewards. Capable of working up to 20 hours a day, these robots clock about 7,000 productive hours a year, far outweighing human efforts. This upswing in productivity is likely to reshape business models and create fresh revenue avenues. Countries that are investing heavily in humanoid robotics might even see their GDP grow remarkably — possibly more than 10% by the early 2030s and a staggering 100% by the late 2030s.

Looking ahead, the market for humanoid robots is slated to hit between $50-100 billion by 2030, with individual robots costing between $20-50k. These machines could operate at a meager cost of $12 an hour, potentially slashing labor expenses for manufacturers and businesses.

Labor Market Shifts: Challenges and Chances

While humanoid robots bring unprecedented efficiency and productivity, they also challenge traditional job markets. Their ability to replace humans in low-skilled and repetitive roles might push wages downwards across various industries. Yet, this technology shift presents opportunities as well — for upskilling and reskilling the workforce. Focused educational and training programs can equip workers with the necessary skills for a tech-driven future.

Enhancing Safety and Efficiency

These robots not only work efficiently but also promote safer workspaces. They can handle hefty or fragile materials, perform quality checks, and assist with repairs and upkeep. By tackling ergonomic challenges, humanoid robots can help reduce the risk of injuries for human workers, making workplaces safer and more efficient.

Expanding Horizons and Future Trends

Humanoid robots aren’t confined to the automotive industry alone. Companies such as Hyundai and key suppliers like Magna International Inc. are also developing and deploying these robots on their assembly lines. Notably, the cost of these machines has dropped by 40% recently, a trend likely to keep moving, fueling rapid growth and potentially creating a $38 billion market by 2035.

In summary, as humanoid robots carve a new path in industrial manufacturing, especially within the automotive sector, they herald a profound shift towards more efficient, adaptable, and safer production methods. Despite the economic and labor market challenges they may bring, their potential for enhancing productivity, safety, and efficiency marks them as a pivotal force in the future of manufacturing.

Leave a Reply