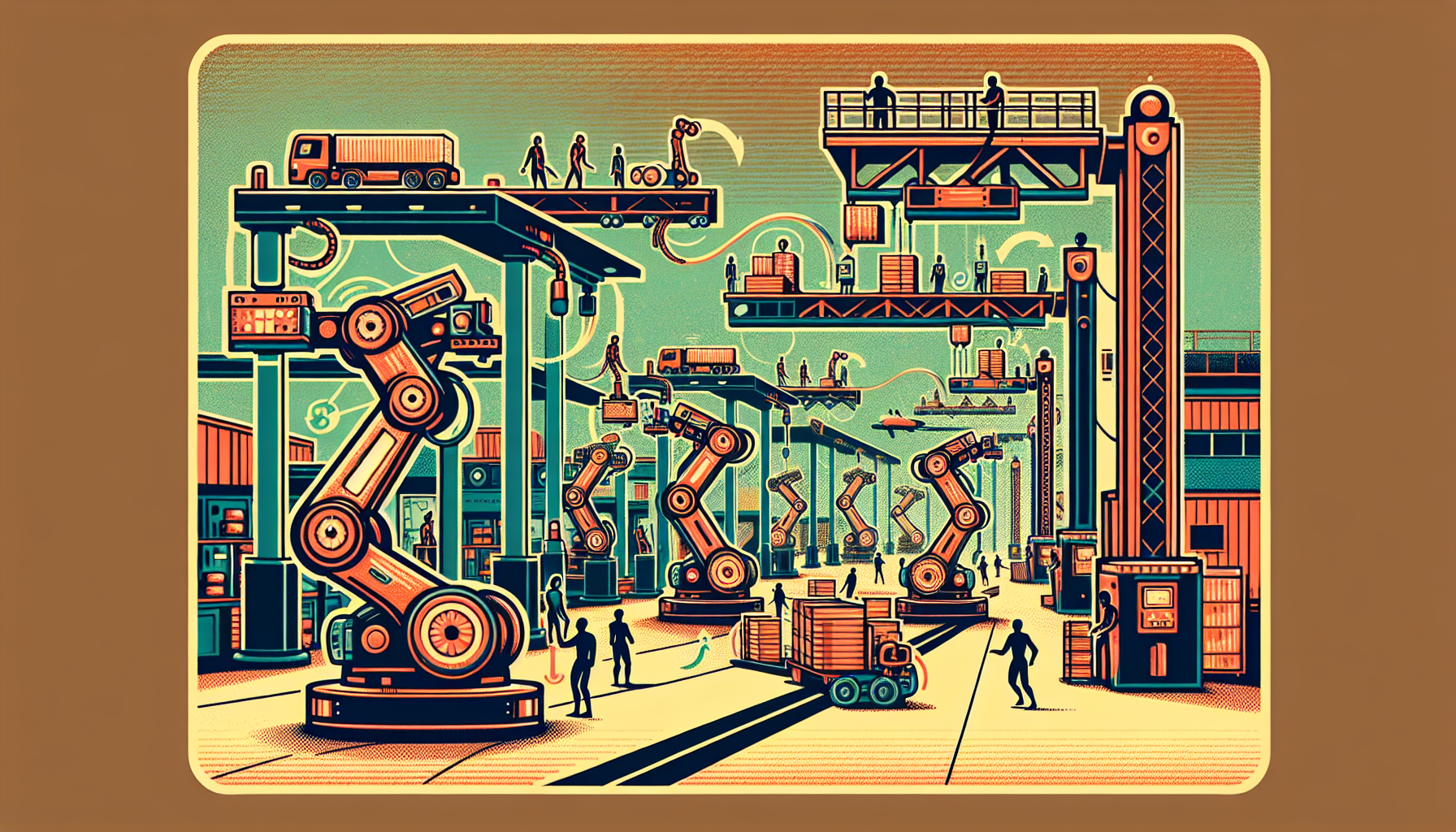

In today’s world of industry, change is happening faster than ever before. At the heart of this transformation are AI-powered gantry robots—machines that are quietly revolutionizing the way we build, move, and deliver goods. Their influence is unmistakable, and recent developments make it clear that these robots are in higher demand than ever.

The Rise of Intelligent Automation

Gantry robots have long been used to automate repetitive tasks in factories and warehouses. But with the arrival of advanced artificial intelligence, these robots are gaining new abilities. AI allows them to recognize objects, make decisions on the fly, and even predict when maintenance is needed. They’re no longer just machines that repeat the same movements—instead, they adapt to changing conditions and work side by side with humans, supporting tasks like picking, placing, assembling, and packaging with remarkable speed and accuracy.

The industry is taking notice. According to recent reports, AmbiStack’s AI-powered gantry robots are already sold out for 2025, with Fortune 500 logistics companies rushing to secure their spot. This rush is more than just a sign of popularity—it is a signal that the future of work depends on intelligent automation.

Why AI-Powered Gantry Robots Matter

The integration of artificial intelligence with gantry robots is not a small step; it is a leap forward. These systems can:

- Take on complex tasks that once required manual oversight

- Offer unmatched precision and speed

- Cut down on duplication and errors in the production process

- Communicate with other machines for seamless operations

Asia currently leads in robotic installations, with more than 70% of the world’s new industrial robots placed in factories across the continent. This shift marks a new era of efficiency, where smart robots are just as essential as any other piece of industrial equipment.

Transforming Manufacturing and Logistics

The sold-out status of AmbiStack’s AI-powered gantry robots shines a light on how urgent the need for intelligent automation is. Now, top companies see smart robotics as critical—not just a way to cut costs, but a requirement for surviving in a demanding global market. The days of treating automation as a luxury are over.

Leading suppliers like ABB, FANUC, Kuka, and Yaskawa continue to shape the industry, but innovative companies pushing AI into the heart of gantry robotics are capturing new attention. They offer tools that adapt, learn, and evolve—laying the foundation for a future where machines and humans create together in harmony.

Looking Ahead

Automation powered by artificial intelligence is becoming a cornerstone for large-scale production and distribution. It means fewer mistakes, faster delivery, and better quality. The rapid adoption of AI-driven gantry robots is proof that industries are moving swiftly to modernize—sometimes faster than the market can keep up.

What does this mean for the future? Tasks previously too complicated or unpredictable for machines are now within reach. As technology continues to mature, we’ll see robots that do more than simply follow instructions. They will anticipate needs, respond to challenges, and help companies deliver in ways that once seemed impossible.

A Turning Point for Industry

AI-powered gantry robots are more than just a new tool—they are a sign of what’s to come. Their popularity, marked by the sellout of supplies for 2025, reflects a broader move toward intelligent, flexible automation. Their impact on manufacturing and logistics is deep and will only grow, guiding industries into a future shaped by speed, accuracy, and smart technology working in concert with human skill.

Leave a Reply