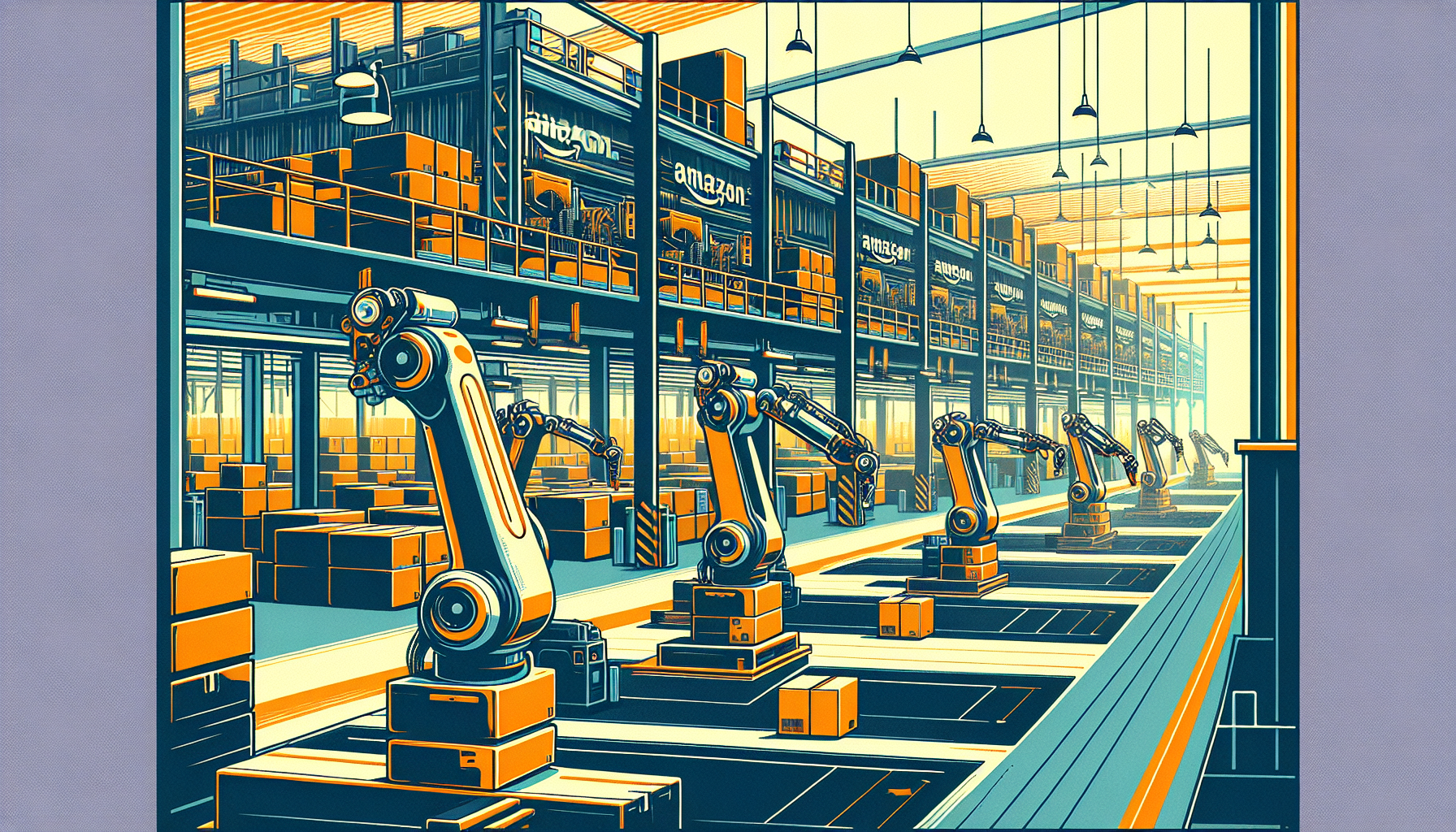

Amazon has made a remarkable stride in enhancing its warehouse operations using advanced robotics. Recently, the company introduced notable innovations at its new fulfillment center in Shreveport, Louisiana. These changes are part of Amazon’s broader mission to integrate state-of-the-art robotics and AI into their logistics framework.

Expanding the Role of Robots

Shreveport’s fulfillment center, known as one of Amazon’s “Gen 12” facilities, boasts a substantial increase in robotic usage—ten times more than earlier warehouses. This leap is part of Amazon’s plan to upgrade existing buildings with new technology rather than constructing new ones. As Tye Brady, Amazon Robotics chief technologist, explains, this strategy allows Amazon to “fix the airplane while it’s flying,” meaning they can introduce new tech into their processes without interrupting their ongoing operations.

Advanced Autonomous Mobile Robots

Central to these new facilities are advanced autonomous mobile robots (AMRs), like the Proteus system, which was showcased at Re:Mars in 2022. These robots are designed to move freely without needing guided paths, making warehouse activities more flexible and efficient. They perform tasks such as lifting and transporting large items, reducing the workload on human workers and increasing productivity.

Robotic Arms and AI Enhancements

Alongside AMRs, Amazon is stepping up its use of robotic arms. These include systems like Robin, Cardinal, and Sparrow, which deal with sorting and stacking items. A noteworthy addition is the Sequoia system, an automated storage and retrieval solution. Originally introduced at the 2023 Delivering the Future event, Sequoia now plays a vital role in the expansive Shreveport warehouse.

AI integration is a vital component of these advancements, boosting the performance of these robotic arms. Collaborating with firms like Covariant, Amazon has improved the abilities of its robotics systems. For example, the Sparrow system now handles a broader range of products thanks to AI, streamlining the sorting and stacking processes further.

Balancing Human and Robot Roles

Despite the emphasis on automation, Amazon stresses the value of human-robot collaboration. Tye Brady notes that humans excel at tasks requiring problem-solving, common sense, and comprehensive thinking, areas where robots still lag behind. Operations needing human dexterity and judgment will continue to rely on human involvement. The growth in robot usage is expected to create job opportunities focusing on robot-related work, such as reliability maintenance engineering. In fact, Shreveport’s center anticipates a 25% uptick in such roles.

Exploring Future Innovations

Amazon is also investigating cutting-edge developments like bipedal robots. At the 2023 Delivering the Future event, Agility’s Digit robot garnered attention. While Amazon has not circulated much information since its pilot program, Brady assures that development is progressing thoughtfully. Challenges persist, particularly in seamlessly incorporating these robots into diverse environments with uneven terrain.

The Path Forward

Amazon’s next-generation robotic warehouse at Shreveport exemplifies a significant advancement in warehouse efficiency and innovation. Through the use of advanced AMRs, AI-driven robotic arms, and fostering human-robot partnerships, Amazon is redefining standard warehouse operations. As the company continues its journey of integrating robotics and AI, the logistics industry is bound to become even more automated and efficient.

Leave a Reply