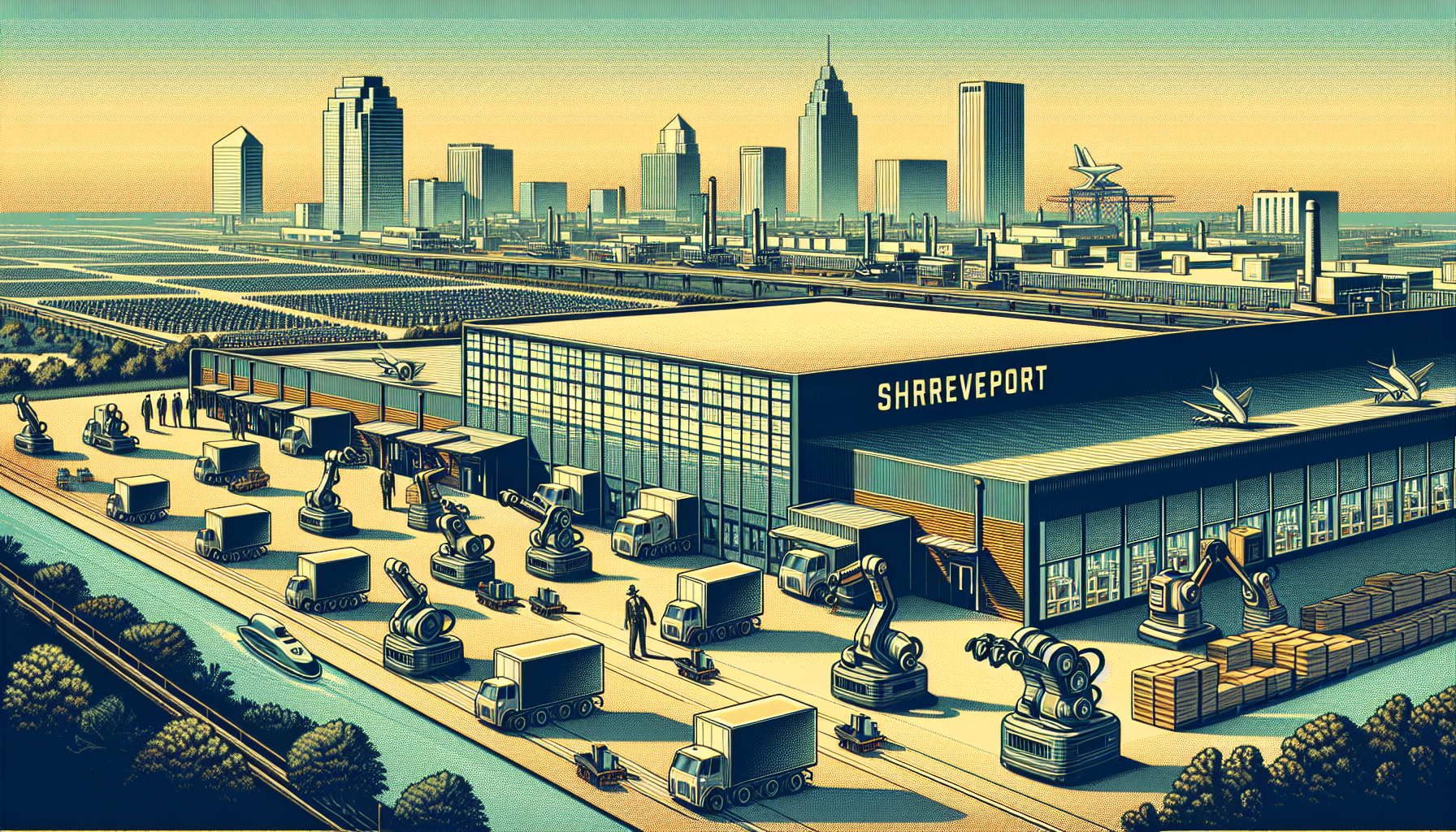

Amazon has just revealed a groundbreaking fulfillment center in Shreveport, Louisiana. This marks a major moment in the company’s journey to blend robotics and artificial intelligence to transform logistics operations.

### Facility Overview

This new fulfillment center is one of Amazon’s largest facilities, sprawling over three million square feet spread across five floors. To put it in perspective, that’s about the size of 55 football fields. Once it’s up and running, around 2,500 people will be employed there, adding a significant boost to the local economy and job market.

### Advanced Robotics and AI

At the core of this cutting-edge facility is a multilevel containerized inventory system called Sequoia. This remarkable system houses over 30 million items, making it significantly larger than its previous version in Houston, Texas. Sequoia manages the activities of thousands of mobile robots and an array of robotic arms to organize and retrieve goods swiftly and effectively, ensuring items are positioned closer to customers for quicker delivery times.

Among the impressive fleet are AI-powered robotic arms known as Robin, Cardinal, and Sparrow. These robots use advanced computer vision and AI to expertly sort, stack, and organize millions of items with precision. Notably, the newest model of Sparrow is capable of handling over 200 million unique products, accommodating a variety of shapes, sizes, and weights.

### Autonomous Navigation and Packaging Automation

Introducing Proteus, Amazon’s first-ever fully autonomous mobile robot, adds another layer of innovation. This robot skillfully guides carts of packages to the outbound dock, ensuring smooth and safe movement among employees in open areas. The facility also embraces Packaging Automation systems that refine the packaging process. These systems switch out plastic for curbside recyclable paper solutions, underscoring the facility’s commitment to sustainability.

### Employee and Customer Benefits

The integration of these cutting-edge technologies reflects Amazon’s vision of collaborative tech that aids employees, boosts safety standards, and enhances sustainability. Tools like Sequoia, Cardinal, and Proteus aim to improve workplace ergonomics and reduce strenuous lifting, significantly advancing safety measures. Amazon reports a remarkable 30% improvement in safety over recent years, with even more expected as these technologies are implemented.

As for customers, they can look forward to faster and smoother deliveries. During peak delivery seasons, Amazon aims to elevate its cost efficiency by 25%, translating to potential savings for customers.

### Environmental and Safety Improvements

Sustainability and safety are key priorities in the design of the Shreveport facility. With the use of recyclable packaging and the refinement of logistics processes, the facility’s environmental impact is minimized. The advanced robotics and AI systems also contribute to decreased injury rates, potentially achieving an 8.5% reduction compared to traditional fulfillment centers.

### Job Creation and Network Modernization

These innovative robotic systems are not just for new facilities. They can be seamlessly integrated into existing buildings, helping Amazon rapidly modernize its entire network for greater efficiency. This next-generation technology will also generate more skilled jobs, requiring 30% more employees in roles like reliability, maintenance, and engineering.

In summary, Amazon’s new fulfillment center in Shreveport, Louisiana, stands as a significant advancement in the company’s application of AI and robotics to reimagine logistics. With its state-of-the-art technologies, safety enhancements, and environmental progress, this facility sets a new benchmark for efficiency and innovation within the industry.

Leave a Reply