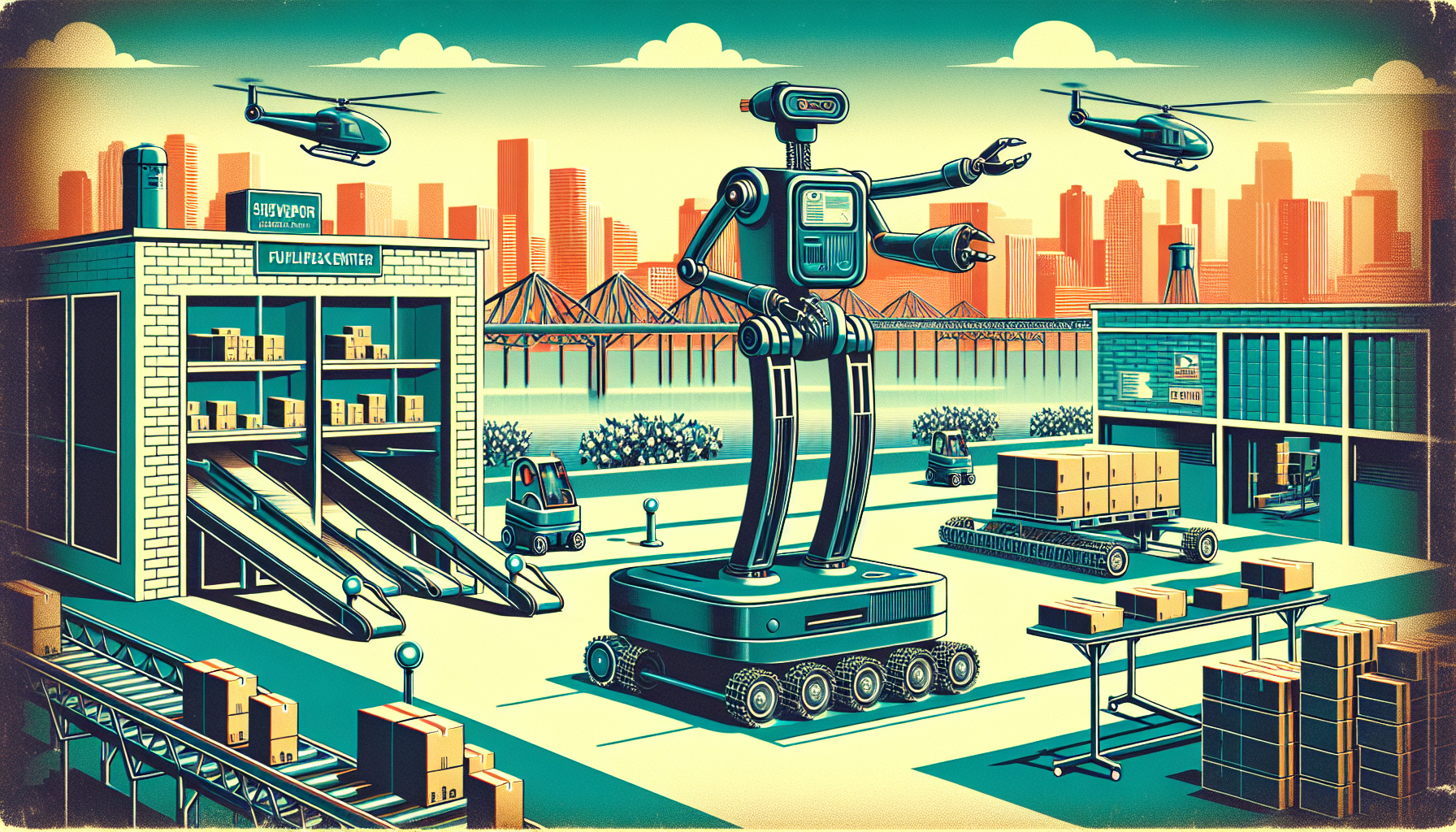

In a groundbreaking move for logistics and warehouse operations, Amazon has introduced its latest marvel: an autonomous mobile robot named Proteus. This state-of-the-art technology is at the heart of Amazon’s cutting-edge fulfillment center in Shreveport, Louisiana, showcasing a powerful combination of artificial intelligence and advanced robotic automation.

Proteus: The Autonomous Trailblazer

Proteus is Amazon’s first fully autonomous mobile robot, engineered to work safely and effectively alongside human colleagues. Unlike previous robots, Proteus roams freely within the fulfillment center, adeptly identifying and avoiding obstacles. This is made possible by sophisticated safety, perception, and navigation technologies developed by Amazon.

Proteus primarily handles the challenging task of lifting and moving large wheeled carts in the warehouse’s outbound areas. These carts, loaded with packages ready for shipment, can weigh up to 800 pounds. By taking on this heavy lifting, Proteus eases the physical workload on employees, reducing the risk of injury and stress. This not only boosts employee health and productivity but also speeds up package processing, ensuring customers get their deliveries faster.

Integrated Robotics Ecosystem

Proteus is part of a comprehensive suite of robotic systems Amazon has created to optimize their fulfillment operations. Here’s a closer look at the robots that collaborate with Proteus:

Hercules

Hercules is pivotal in Amazon’s goods-to-employee system, retrieving items from inventory and delivering them to packing stations. This lets staff concentrate on more complex tasks like packing and labeling. Hercules operates independently, guided by centralized planning software, and uses a 3D camera to safely navigate around people and objects.

Pegasus

Pegasus, built on the Hercules platform, specializes in sorting finished parcels by zip code or delivery route. Featuring a mini-conveyor belt, it expertly navigates the sortation center’s structured environment.

Cardinal

Cardinal is a robotic workcell using AI and computer vision to select, lift, and place packages into GoCarts. By taking on tasks involving heavy lifting, it minimizes employee injury risk and transforms manual work into a seamless automated process.

Sequoia

Sequoia enhances storage efficiency by consolidating inventory, enabling quicker order processing. It uses AI, robotics, and computer vision to deliver items directly to ergonomically designed workstations, minimizing the need for employees to make potentially strenuous movements.

AI and Safety Enhancements

Amazon’s Shreveport fulfillment center stands as a testament to the company’s dedication to innovation and safety. The fusion of AI within its robotic systems ensures smooth and efficient operations:

- Advanced Navigation and Safety: Proteus and other robots utilize cutting-edge navigation technology to avoid collisions and safely interact with people, employing 3D cameras and floor markers for guidance.

- Automated Package Handling: With robots like Cardinal and Proteus, tasks such as lifting heavy packages are automated, reducing injury risks and allowing workers to focus on more rewarding jobs.

- Enhanced Productivity: The robots are expected to elevate productivity by 25% in new fulfillment centers through superior AI and robotic integration.

Employee Benefits and Sustainability

These autonomous robots aim not only to boost efficiency but also to improve employee experience and support sustainability goals:

- Employee Safety and Satisfaction: A study by Amazon and MIT reveals that 60% of employees anticipate a positive impact from robotics and AI on their productivity and job satisfaction. Proteus and Cardinal help minimize physical strain, enhancing employee health and productivity.

- Sustainability Initiatives: Amazon has eliminated plastic air pillows in its packaging, converting to fit paper bags, thus saving over 130 million plastic bags this year. Their Climate Pledge Fund backs technologies aimed at reducing electronic waste and carbon footprints.

In summary, Amazon’s advancements in autonomous robotics, demonstrated by Proteus and its integrated robotic systems, represent significant progress in logistics and warehouse management. These innovations not only boost efficiency and customer satisfaction but also put a strong emphasis on employee well-being and sustainability. As Amazon continues to innovate with AI and robotics, the future of logistics promises to be more automated, efficient, and environmentally friendly.

Leave a Reply