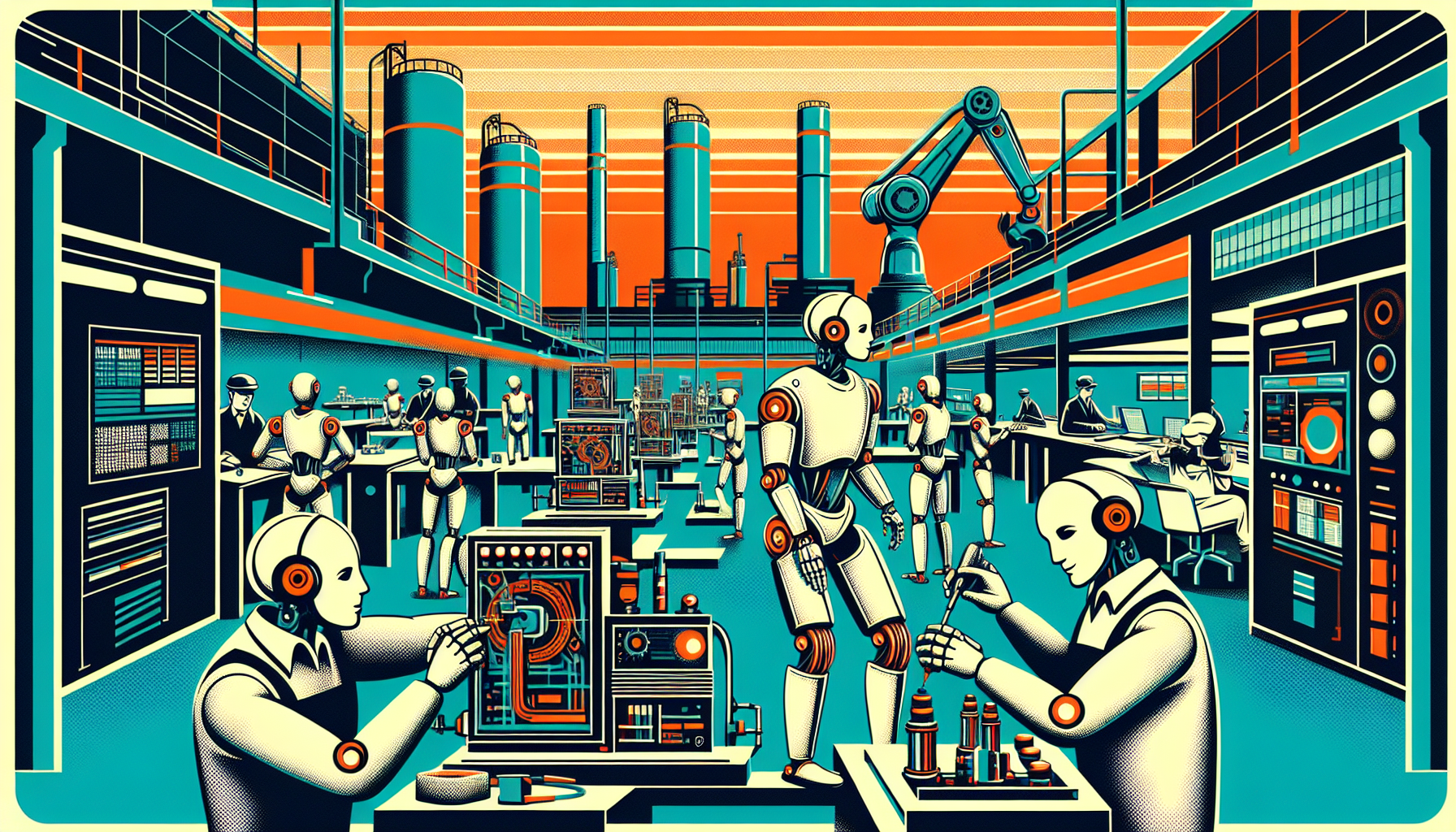

Foxconn and Nvidia are joining forces to bring humanoid robots into the heart of manufacturing in Houston, Texas. At Foxconn’s new facility, these advanced machines will help assemble Nvidia’s state-of-the-art AI servers. This partnership is more than just a business move—it marks a powerful step forward in industrial automation and robotics, with the promise to reshape how manufacturing is done in America.

A New Era for Manufacturing

At the center of this announcement is the upcoming Houston plant, which will begin assembling Nvidia’s GB300 AI servers as early as 2026. This factory will stand out as the first in the world to use humanoid robots on its production lines for AI servers. Rather than just working alongside humans, these robots will perform intricate assembly tasks, bringing a new level of intelligence and flexibility to the manufacturing process.

Foxconn, known as the world’s leading electronics manufacturer, is closely collaborating with Nvidia on this project. Their shared goal is to create robots that can handle the type of work that has traditionally required human skill and attention. This partnership represents a major shift in how factories are run—moving from simple automation to smarter, more adaptable robotics.

The Role of Humanoid Robots

The technology behind this effort is remarkable. The humanoid robots are being developed in partnership with Nvidia’s Isaac GR00T platform, which leverages artificial intelligence to train robots for highly detailed, repetitive jobs. The types of tasks these robots will handle include inserting cables, placing delicate components, and checking the quality of each AI server as it is made.

Foxconn has designed two kinds of humanoid prototypes for this mission. One has legs, giving it the freedom to move in any direction and handle a range of tasks. The other is built on wheels, offering a practical and lower-cost solution for specific jobs. Both are trained to mirror the dexterity and accuracy typically seen only in skilled human workers. Building the facility in Houston—where space is plentiful—makes it possible to deploy and test these robots without the limitations often found in older, crowded factories.

Why This Partnership Matters

This collaboration is part of a larger movement across the manufacturing world. Car companies such as Mercedes-Benz, BMW, and Tesla are also looking at humanoid robots for their own plants. By jumping ahead with this technology, Foxconn and Nvidia aren’t just improving their own production—they’re helping set new standards for the entire industry.

Other partners, like HEXAGON, are also involved and working on robotics solutions that will expand the manufacturing ecosystem. The goal is not just efficiency—though that is important—but also competing at the highest levels in areas where both precision and scale are critical. Introducing humanoid robots to U.S. factories could drastically boost America’s role in high-tech manufacturing.

Looking Ahead

Soon, these breakthroughs will be on full display. Foxconn plans to reveal both the legged and wheeled robot models at its annual technology event later this year. When the Houston factory becomes fully operational in early 2026, it will signal a turning point: the first use of humanoid robots for mass production in the United States on this scale.

What happens in Houston is likely to echo far beyond one factory. As these robots prove their worth, it could inspire other companies—and other countries—to adopt similar technologies. The ability to build complex electronics with both speed and care is expected to become the new standard in manufacturing.

A Landmark Innovation

The alliance between Foxconn and Nvidia is more than a technical project—it’s a glimpse into the future of industrial work. By merging artificial intelligence with robotics, they are showing the world a new way forward—one where strengths of both humans and machines are brought together on the assembly line.

Through this partnership, Foxconn and Nvidia are not only advancing their businesses but also opening doors for new kinds of jobs, smarter technologies, and a reinvention of what factories can achieve. The dawn of humanoid robot-assisted manufacturing begins in Houston, and its impact will be felt for years to come.

Leave a Reply