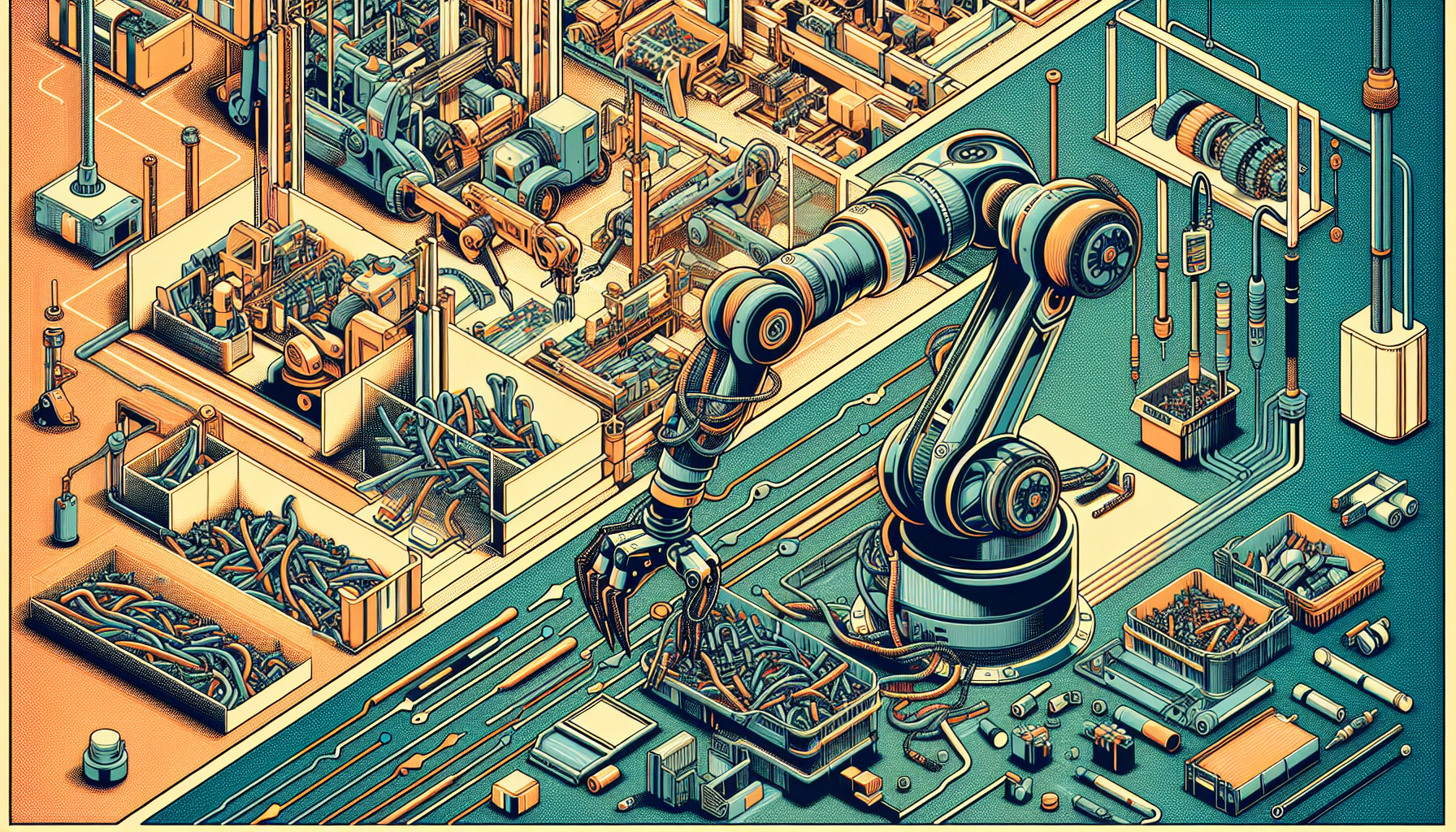

In the realm of modern automation, AI-powered robotic grippers have emerged as revolutionary tools. They blend flexibility, precision, and energy efficiency to transform how industries operate, from manufacturing to waste management. This fascinating advancement is not just about improving efficiency; it’s about moving towards a more sustainable industrial future.

### Unveiling the Core Features

The magic of AI-powered grippers lies in their remarkable ability to handle tasks with a human-like touch. Using machine learning and computer vision technologies, these grippers can understand and manipulate a variety of objects in real-time. It’s like giving robots the delicate skills of a human hand, making them ideal for both complex and gentle tasks.

Equipped with advanced sensing technologies, these grippers utilize tactile sensors and force feedback mechanisms. This allows them to gauge the correct amount of pressure, adapting seamlessly to an object’s characteristics. Such adaptability is crucial, especially for delicate manufacturing processes where precision is paramount.

Designed to collaborate with humans, these grippers take over repetitive, strenuous tasks. This synergy lets human workers shift their focus to more nuanced aspects of their roles, like problem-solving and innovation. By working hand-in-hand with people, these robots enhance workspace efficiency and creativity.

### Innovations Leading the Charge

Recent breakthroughs highlight the dynamic evolution of gripper technology:

– **Soft Robotics and Kirigami Grippers**: At North Carolina State University, researchers have introduced grippers based on the art of kirigami. This technique involves cutting and folding materials into three-dimensional shapes. The result is grippers capable of handling both fragile and heavy objects with a gentle yet firm grip, promising applications in fields like robotic prosthetics.

– **Tape-Based Agricultural Grippers**: Engineers at the University of California San Diego have crafted a unique gripper using measuring tape, known as GRIP-tape. This ingenious creation shows promise in agriculture, particularly for managing delicate fruits and vegetables. It’s a solution that balances flexibility with cost-effectiveness.

– **Energy-Efficient Innovations**: At Saarland University, a team has developed grippers using shape memory materials, significantly reducing energy requirements. These lightweight, self-sensing grippers adapt quickly to various workpiece shapes, making industrial processes more efficient and energy-conscious.

### Transforming Industries and Promoting Sustainability

AI-powered robotic grippers are reshaping multiple sectors:

– **Boosting Efficiency**: By automating intricate tasks and working alongside human colleagues, these grippers slash error rates and supercharge productivity. This is vital in sectors such as manufacturing and healthcare, where precision and efficiency can make or break outcomes.

– **Championing Sustainability**: Companies like Waste Robotics are leveraging these technologies to refine waste management. By sorting materials with pinpoint accuracy, they lower contamination levels and boost recyclables’ quality, paving the way for a more sustainable future.

– **Maximizing Energy Efficiency**: Through the integration of lightweight materials and smart sensing technologies, these grippers reduce energy consumption remarkably. For instance, the innovation from Saarbrücken presents a noteworthy example, achieving up to 90% energy savings over traditional grippers.

Ultimately, AI-powered robotic grippers stand as a testament to the advances in automation technology. They offer enhanced efficiency and precision while also moving vital industries towards sustainability. As these innovations continue to unfold, robotic grippers are destined to play a pivotal role in shaping the future of manufacturing, healthcare, and environmental stewardship.

Leave a Reply