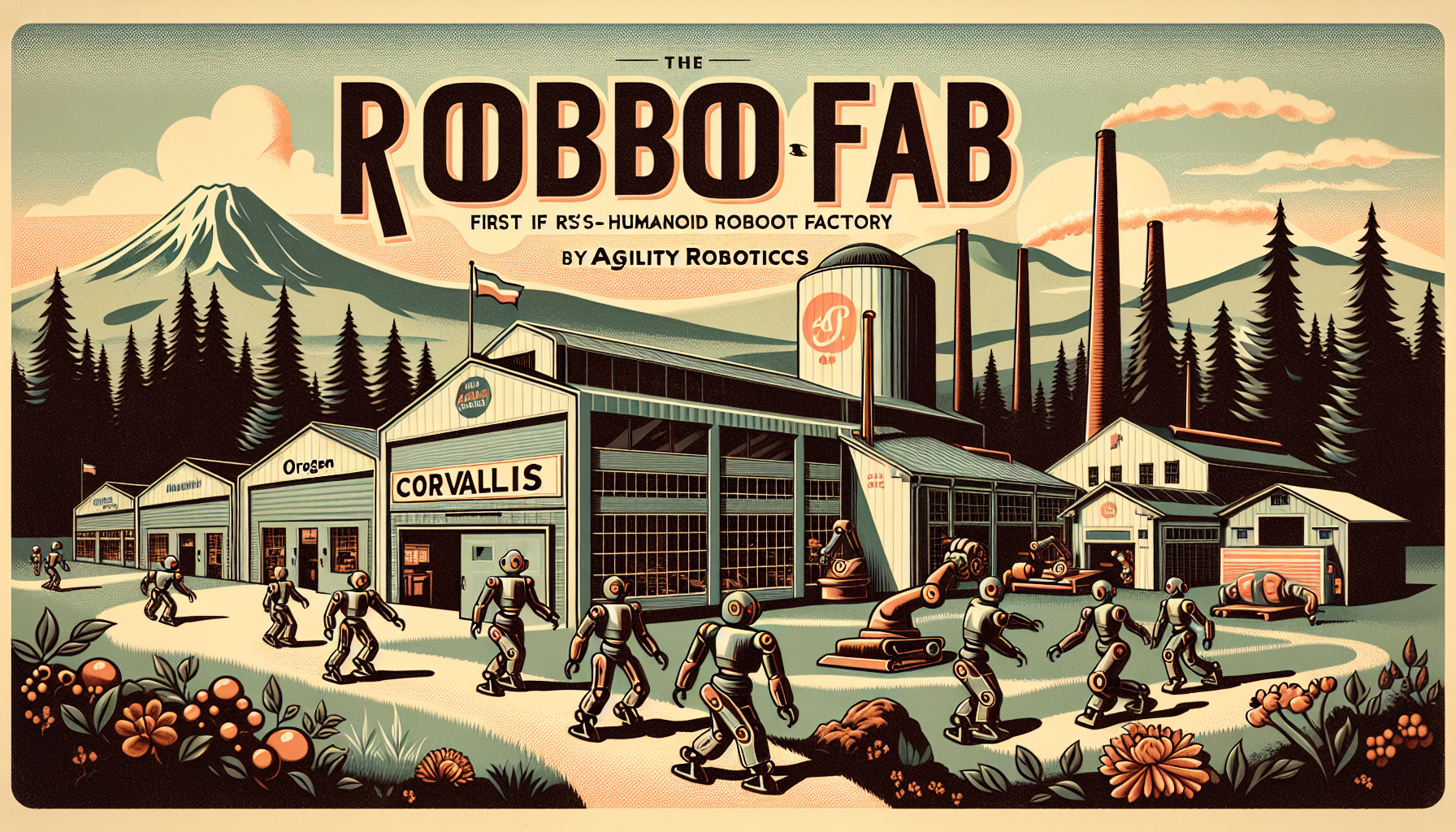

In the heart of Corvallis, Oregon, a pioneering company called Agility Robotics is changing the landscape of humanoid robotics. Their groundbreaking achievement, the establishment of RoboFab, the first-ever humanoid robot factory, signals a transformative moment for the industry.

RoboFab: Cutting-Edge Manufacturing for the Future

Nestled in Salem, Oregon, RoboFab is a sprawling 70,000-square-foot marvel of technological advancement. This facility will soon be buzzing with the production of Digit, the company’s premier robot, by the end of 2024. Initially, RoboFab aims to craft hundreds of these robots annually, with ambitions to scale up production to a remarkable 10,000 robots each year.

Meet Digit: A Robot for Human Spaces

Digit, Agility Robotics’ innovative bipedal creation, is built to smoothly operate in environments designed for humans. With a height of 5 feet 9 inches and the ability to carry up to 35 pounds, Digit is equipped with sophisticated LIDAR and stereo cameras. These technologies allow Digit to autonomously perceive its surroundings, dodge obstacles, and navigate fluidly.

Already, Digit has begun to show its versatility. In a Spanx warehouse, it has successfully taken on material handling tasks. Meanwhile, Amazon is exploring its potential at a facility near Seattle, highlighting Digit’s promise in addressing labor shortages and boosting human workers’ quality of life by handling monotonous and hazardous tasks.

Technological Marvel: Advanced Features and Integration

The latest version of Digit boasts state-of-the-art actuators at its joints, alongside advanced circuits and sensors mirroring a human’s complex nervous system. Agility Robotics is committed to ensuring that Digit can seamlessly operate alongside humans, making it an engineering marvel.

Ongoing efforts to integrate artificial intelligence (AI) into Digit’s design aim to enable the robot to understand and execute verbal commands. This advancement will enhance Digit’s ability to tackle tasks such as navigating stairs and doorways, making it even more adaptable to a variety of roles within logistics and manufacturing sectors.

Strategic Collaborations and Industry Influence

In a bid to widen its influence, Agility Robotics has forged a partnership with Manhattan Associates, a global leader in supply chain commerce. This collaboration seeks to integrate Digit and the Agility Arc cloud automation platform with Manhattan’s Active Warehouse Management solution, boosting efficiency and addressing workforce challenges.

Guiding Principles: Vision and Mission

Driven by a mission to create robotic partners that complement human workers, Agility Robotics aims to empower humans to concentrate on more creative and socially interactive tasks. Co-founder Jonathan Hurst envisions a future where “humans are more human,” free from the burden of tedious, dirty, and dangerous chores.

Economic Growth and Job Creation

Upon reaching full production, the RoboFab facility is anticipated to employ over 500 individuals, significantly boosting the local economy and presenting numerous high-skilled job opportunities throughout the Willamette Valley. The strategic location in Salem, Oregon, plays a key role in attracting skilled engineers and computer scientists from nearby cities such as Portland, Albany, and Corvallis.

Agility Robotics’ establishment of RoboFab signifies a momentous leap in robo-technology, paving the way for the mass production of commercial humanoid robots. Leading the charge with Digit, Agility Robotics is poised to dramatically reshape various industries by delivering versatile, human-friendly robots that can work harmoniously alongside people. As demand for such technologies surges, Agility Robotics stands at the forefront, set to redefine the future workspace and enhance human quality of life.

Leave a Reply