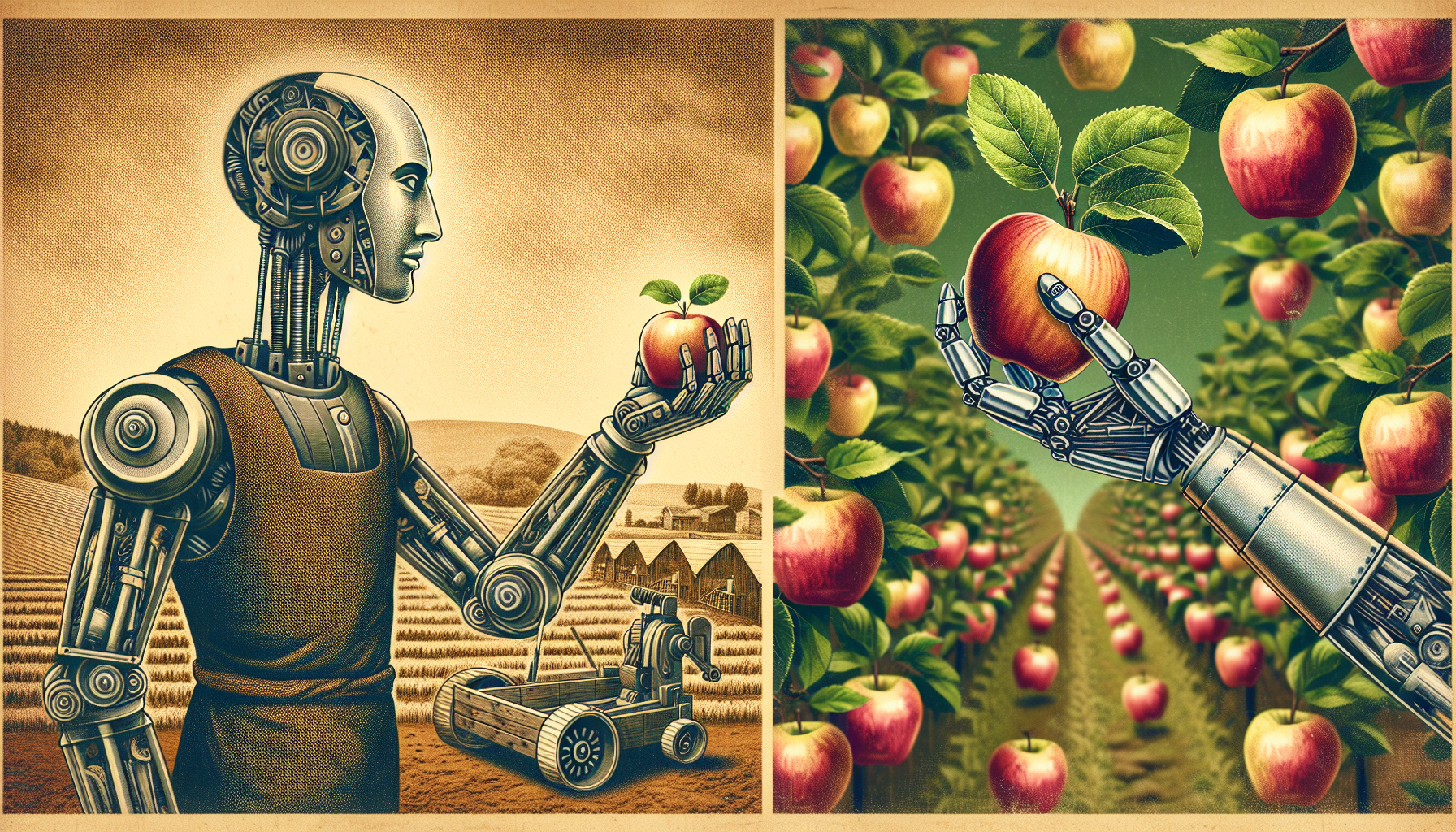

In the world of farming, harvesting fruits and vegetables has always needed a gentle touch. Traditional robotic hands often struggled—too stiff to handle soft produce without causing bruises, too bulky to work efficiently in crowded fields. Now, a new invention gently changes all of that. The GRIP-tape robotic gripper, designed by engineers at UC San Diego, is inspired by the humble mechanics of a measuring tape. This simple but brilliant design is set to transform how robots pick produce, making the process both efficient and careful.

Inspired by Simplicity

GRIP-tape takes lessons from something found in every toolbox: the measuring tape. It uses two spools, each holding twin rolls of tape that are both strong and flexible. These rolls are guided by four small motors, giving the gripper independent control over each “finger.” Unlike older machines that require large mechanisms to reach for objects, GRIP-tape remains compact until it needs to open—making it easy to fit into tight, leafy spaces on crowded branches.

How It Works

When the gripper is ready to pick a piece of fruit or a vegetable, its tape “fingers” quietly unroll and extend. Guided by precise motors, they wrap gently and exactly around the chosen item. The tape’s natural curve helps the fingers conform to the object, providing a careful but secure grip. The motors can even rotate the object in place, allowing for skillful harvesting and handling. When the job is done, the tapes retract, and the gripper becomes compact again, ready for its next task.

Why Measuring Tape?

The secret is in the material. Measuring tape—usually made from thin, springy steel—has rare qualities:

- Soft Edges: The tape is as gentle as silicone, which means it handles fragile fruit without harming it.

- Strength: The steel is strong enough to lift and move produce without bending under weight.

- Flexibility: Its springiness easily adapts to odd shapes and holds tight—even when the fruit is round, bumpy, or awkwardly positioned.

This blend of gentleness and strength is what makes GRIP-tape uniquely suited to carefully picking everything from delicate strawberries to oddly shaped tomatoes.

Modern Solutions for Modern Farms

GRIP-tape was built with farms in mind. In fields where space is tight, and fruit can be hidden behind leaves, a small but skillful machine is needed. The gripper’s compact form allows it to slip past branches and reach otherwise hard-to-access produce, all without crushing nearby plants. Its safe, non-threatening design means it can also work closely with people, making it ideal for farms where humans and robots might harvest side by side.

Beyond its clever design, GRIP-tape is cost-effective. Traditional expanding grippers use far more parts, making them heavy and expensive. With fewer moving pieces, the measuring tape mechanism keeps things simple and reliable. Because the technology is affordable, it opens the door for more farms to use gentle automation, boosting productivity and reducing both waste and labor costs.

A Step Forward in Robotic Harvesting

The development of GRIP-tape has been published in the journal Science Advances, where researchers share how this invention marks a new era for agricultural robotics. Using tape’s unique physical qualities to solve stubborn challenges, the device blends common hardware with high-level engineering in a way that feels both obvious and inspired.

Nick Gravish, the project’s senior author, captures the technology’s spirit perfectly: “The tape measure is such a wonderful structure because of its combined softness and stiffness together.” This thoughtful union is what allows GRIP-tape to succeed where others have struggled—moving with the delicacy of a skilled human hand while harnessing the quiet strength of robotics.

By turning a simple tool into a sophisticated fruit picker, GRIP-tape promises a future where automated harvesting is not just possible, but careful, efficient, and truly respectful of nature’s fragile bounty.

Leave a Reply